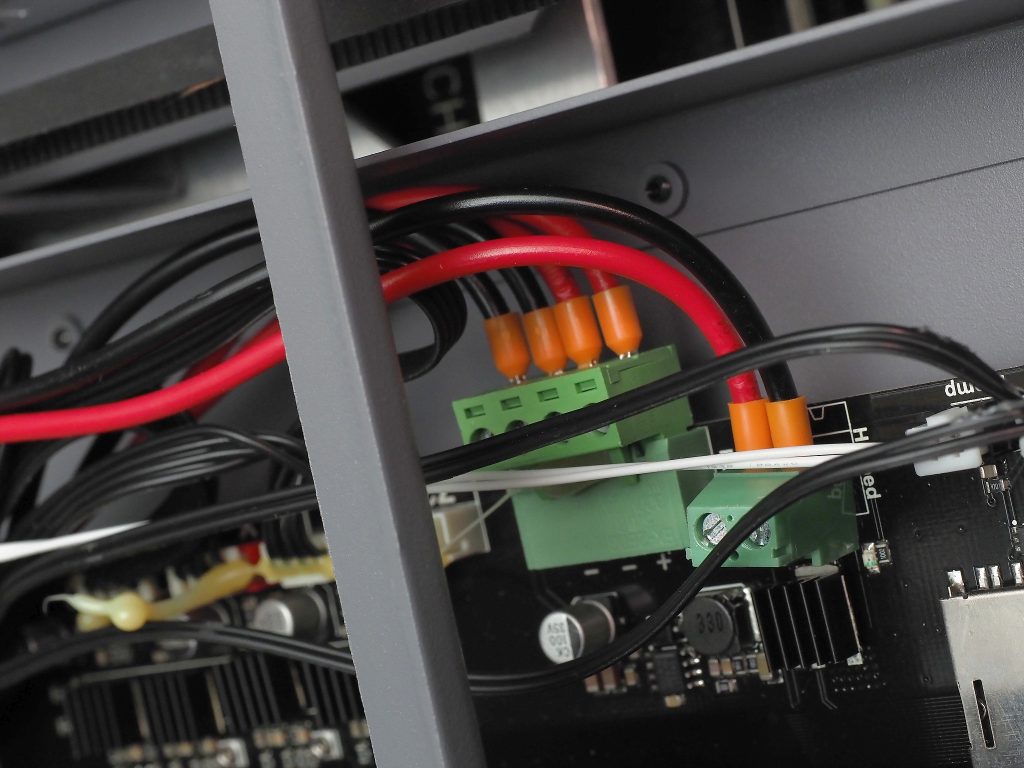

Today I spent some time doing some maintenance. I fixed a squeaky idler, and crimped bootlace ferrules to all the wires that go to screw terminals. Many 3D printers use heavily tinned wires for screw terminals. This is potentially dangerous as the solder can cold flow, leaving the wire sitting loosely within the terminal, leading to poor conduction and heat. There are numerous examples on 3d printer forums of screw terminals that have melted for this reason.

Generally I check the terminals in my printers every few months or so (More regularly if it’s a new machine). Even with regular tightening, the screw terminals still loosen up over time as the solder moves around the wires. It’s unwise to assume that all the terminals on your printer are safe, based on how long it’s been operating for. Poor conductivity in screw terminals due to cold flow becomes more likely as a printer gets older.

I don’t need to write up much on the subject as Hackaday already covered it thoroughly. Considering how inexpensive a set of ferrules and a tool is, I’d recommend replacing the soldered ends of wires with ferrules, or at the very least, keeping an eye on the tension of screw terminals in your printer.