You can buy the magnetic stirrer here: https://www.etsy.com/au/listing/1383287841/

Files are available here: https://www.printables.com/model/330833-magnetic-stirrer

Or, if you’d rather buy me a coffee for my design work, https://www.etsy.com/au/listing/1347129276

Many years ago I designed this magnetic stirrer. It was designed specifically for fieldwork and had the following design criteria:

- It had to be usable in the field or the lab.

- Therefore, it had to be compact and easy to store and transport,

- ……and that includes the magnetic stirrer bars…..

- And it would need to run on batteries,

- Which should be easily replaceable rather than built in.

- As it also had to double as a lab stirrer, it also required power for long term use.

- It had to stir volumes from 10 to 1000 ml.

- It had to be feasible to fabricate.

- It had to be resistant to spills and chemicals.

The original design featured an ABS casing. ABS was chosen as PETG was relatively new at the time and was challenging to print, particularly with regard to supports. As the original design featured replaceable batteries, supports were required for the battery bay as well as for various compartments and doors.

Recently I decided to revisit the design, with a complete rework from the ground up. The goal was to simplify the design and fabrication process, and improve the usability of the stirrer.

Starting with the electronics, I decided that the need for replaceable batteries was no longer valid. Powerbanks, solar chargers, and similar are now commonplace so recharging in the field is much less of a concern. Switching to LiPo batteries simplified the electronics further as there was no need for a power multiplexer and it could be replaced with a (very common) USB powered lithium battery charger. A new slim motor was identified that was less than half the height of the original options.

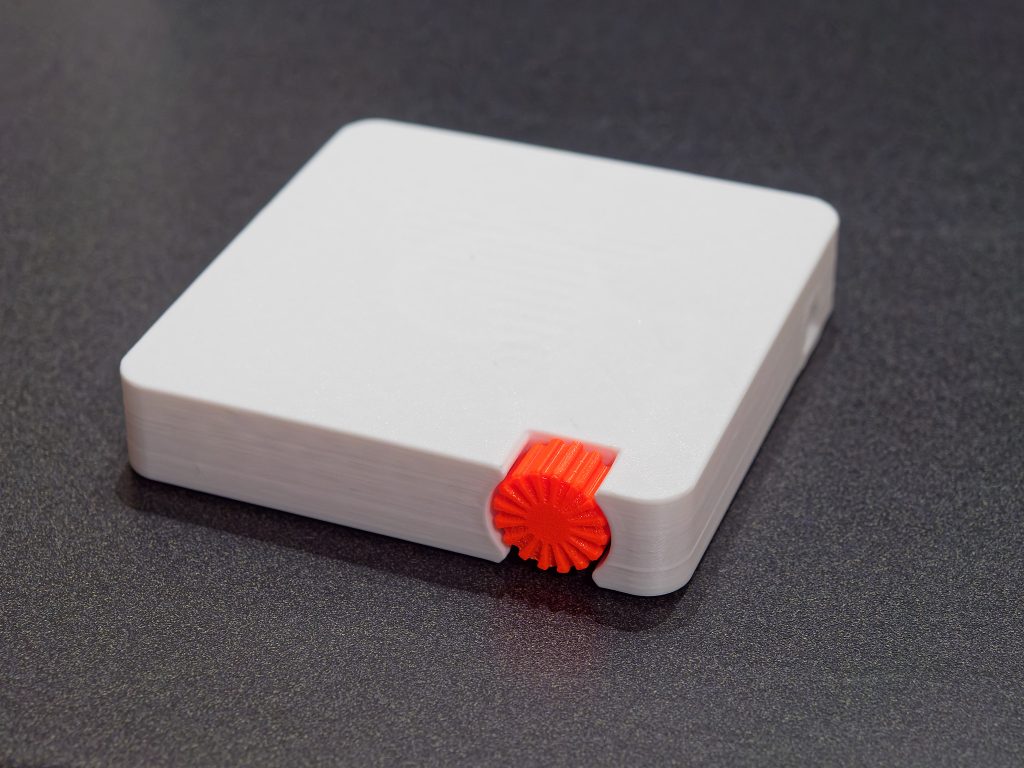

Removing the need for replaceable batteries meant that the stirrer no longer required an openable battery bay. PETG is also commonplace now with well established profiles. As PETG doesn’t warp like ABS does, the new design no longer relies on a shell with a web-structure to support the lid. Instead, the lid and base are essentially solid, with holes cut out for the electronics. A large chamfer is used in the lid to avoid the infamous “Benchy hull line”.

The new motor allowed for a much thinner design. This posed a challenge for mounting the control dial which was resolved by moving the control dial inwards, the new control knob is very well protected from damage during transport, while also being easy to use.

The thinner design made the old drainer/storage drawer a problem. With only 25mm in thickness to work with the drawer would take up too much room and make whichever corner it was mounted in quite weak. Instead a magnetic stir bar retainer was developed, combined with a slot to store the store bar when not in use.

The new design has many improvements over the original and improves usability, ergonomics, robustness and overall dimensions while simultaneously simplifying the fabrication process.

- – The new motor is a much better match for the stirring capability, offering more control over small volumes and is extremely quiet.

- The design is more robust. The control dial is now contained within the main body and is much less likely to be crushed during transport.

- The new battery/charger system means that it no longer has separate voltages (5V on USB and 3V on AA batteries) so the stirrer behaviour is consistent regardless of power source.

- The filled volume makes the stirrer feel much more robust. It’s very much a solid unit rather than a plastic shell.